Enzymes

Enzyme function and structure

Enzymes are biological catalysts - they speed up the rate of chemical reactions happening inside our body. They work by reducing the activation energy of a reaction. Activation energy is defined as the minimum amount of energy needed for a reaction to happen. If less energy is needed, then reactions can take place as lower temperatures than would be needed without an enzyme. Without the enzymes in our bodies, the reactions that happen inside of us would not be possible at normal body temperature. Remember that enzymes are unchanged at the end of a reaction which means they can be reused.

Enzymes can be classed as either intracellular if they catalyse reactions inside cells e.g. RNA polymerase, or extracellular if they catalyse reactions outside of cells e.g. amylase. All enzymes are globular proteins and have regions called active sites. The active site of an enzyme has a specific shape and allows the substrate to bind. Other enzymes may have regulatory regions where an inhibitor can bind, which we refer to as the allosteric site.

Mechanisms of enzyme action

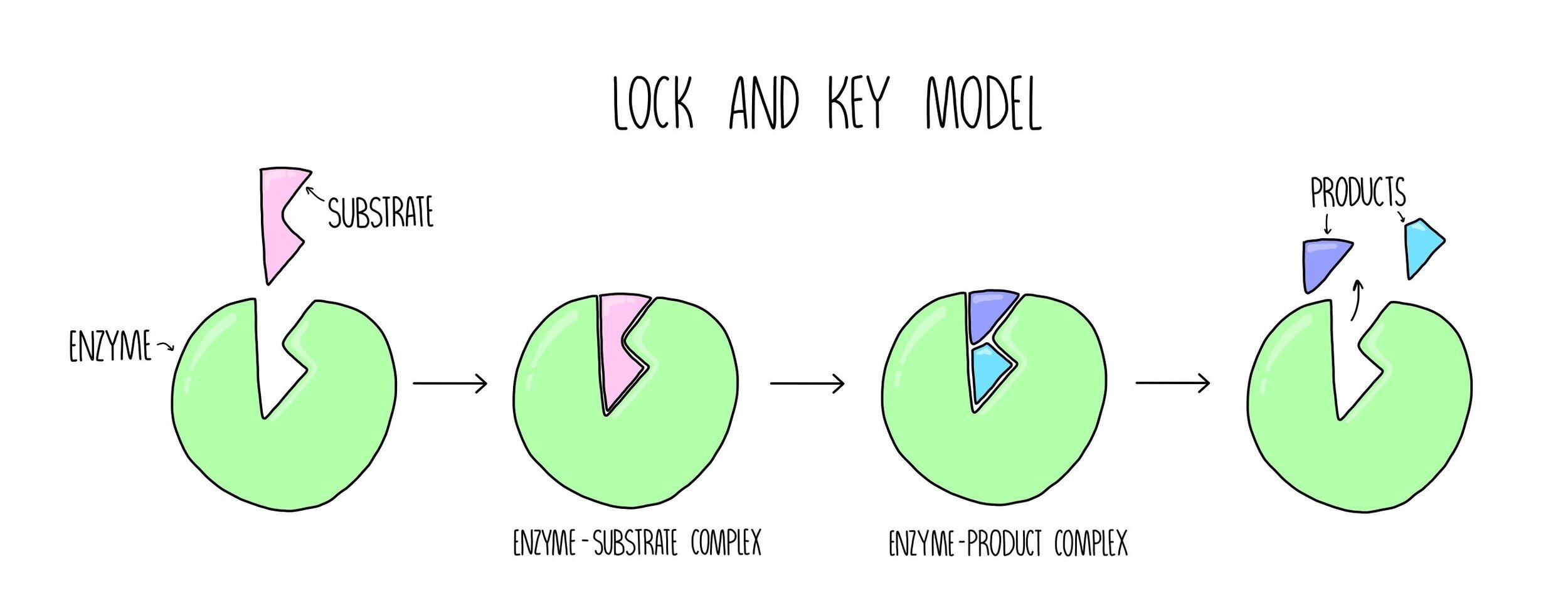

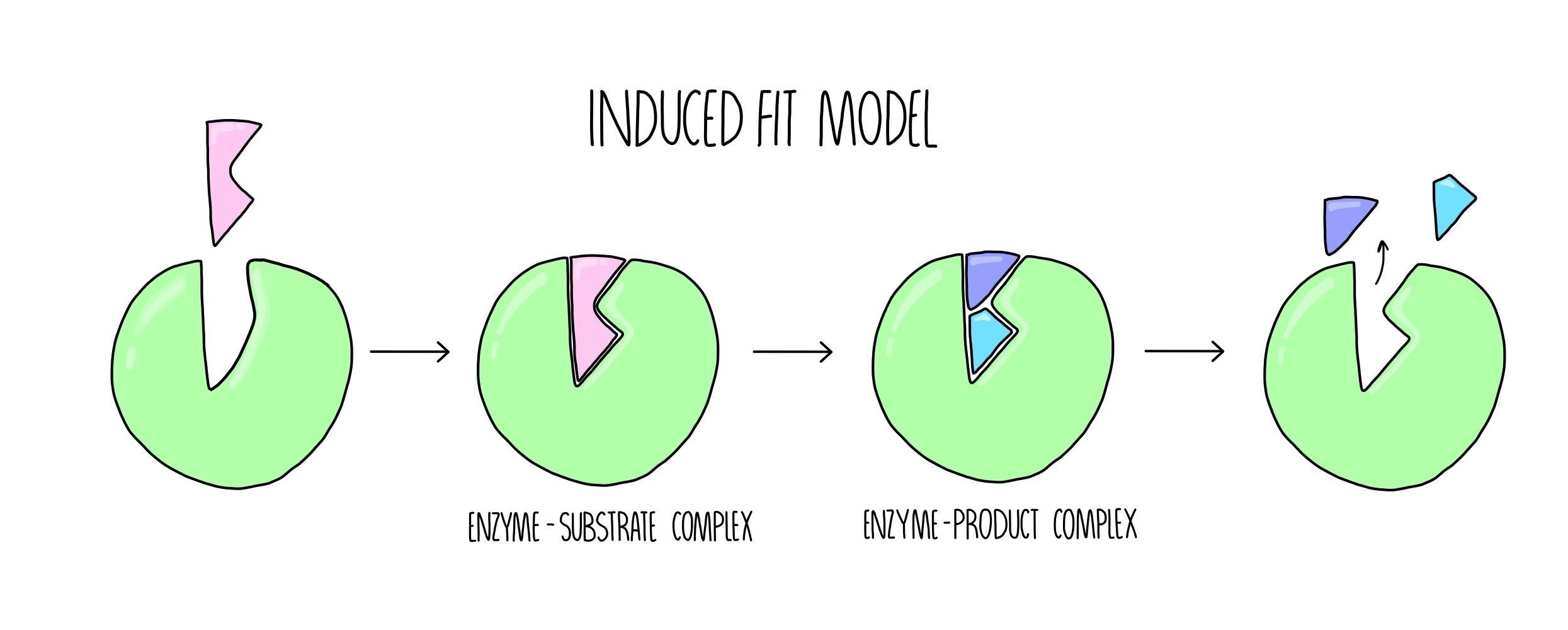

Scientists have two ideas to explain the way in which enzymes work: the ‘lock-and-key’ model and the ‘induced-fit’ model. They are models because they are our best-accepted theories based on the evidence we have available.

Lock and Key model

The lock and key model is the simpler of the two theories of enzyme action. This model suggests that the substrate fits into the enzyme’s active site in the same way in which a key fits into a lock. The shape of the substrate and the active site are perfectly complementary to each other. Catalysis happens in the following stages:

The substrate binds to the enzyme’s active site, forming an enzyme-substrate complex (ES complex).

The enzyme converts the substrate into product, forming an enzyme-product complex (EP complex).

The product is released from the enzyme’s active site.

The Induced Fit model

The induced fit model suggests that the shapes of the enzyme’s active site and its substrate are not exactly complementary, but when the substrate enters the active site, a conformational change (change of shape) occurs which induces catalysis. The induced fit model can be broken down into the following stages:

The substrate enters the enzyme’s active site, forming an ES complex.

The enzyme undergoes a conformational change which causes the conversion of substrate into product, forming an EP complex.

The product is released from the enzymes active site.

Comparing the two models of enzyme action

The advantage of the lock-and-key model is that it explains why most enzymes display such high specificity to their substrates. Each enzyme will catalyse only a certain type of reaction and will only bind to a single specific substrate out of the millions of different molecules that are floating around our bodies. However, not all enzymes catalyse a single chemical reaction. For example, lipase exhibits broader specificity and can bind to a variety of lipids, which only the induced fit model is able to explain. In addition, the induced fit model is better able to explain how catalysis actually occurs. A conformational change, which would place stress on the bonds within the substrate, can explain how bonds would break in order for the products to form. This makes the induced fit model the more widely accepted model of the two.

Factors which affect rate of reaction

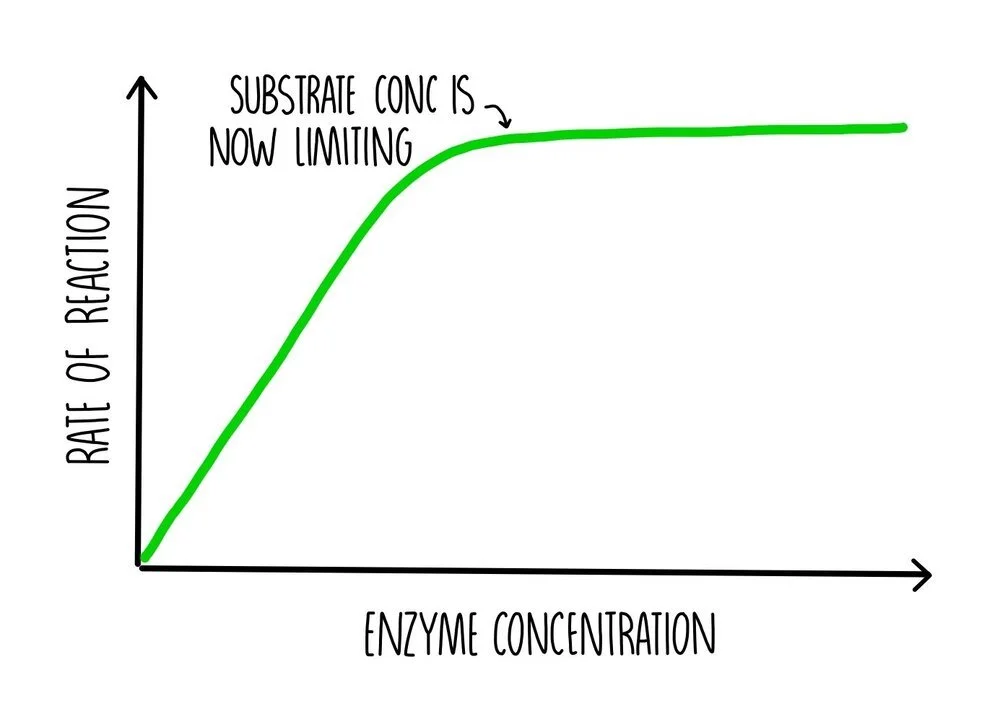

Enzyme concentration

As enzyme concentration increases, the rate of reaction increases since more active sites will be available to bind to substrate molecules. This means that there will be more frequent collisions between the enzyme and substrate, so there will be more formation of enzyme-substrate complexes. However, a point will be reached when increasing enzyme concentration does not result in further increases in reaction rate. At this point, something else has become a limiting factor, such as the availability of substrate.

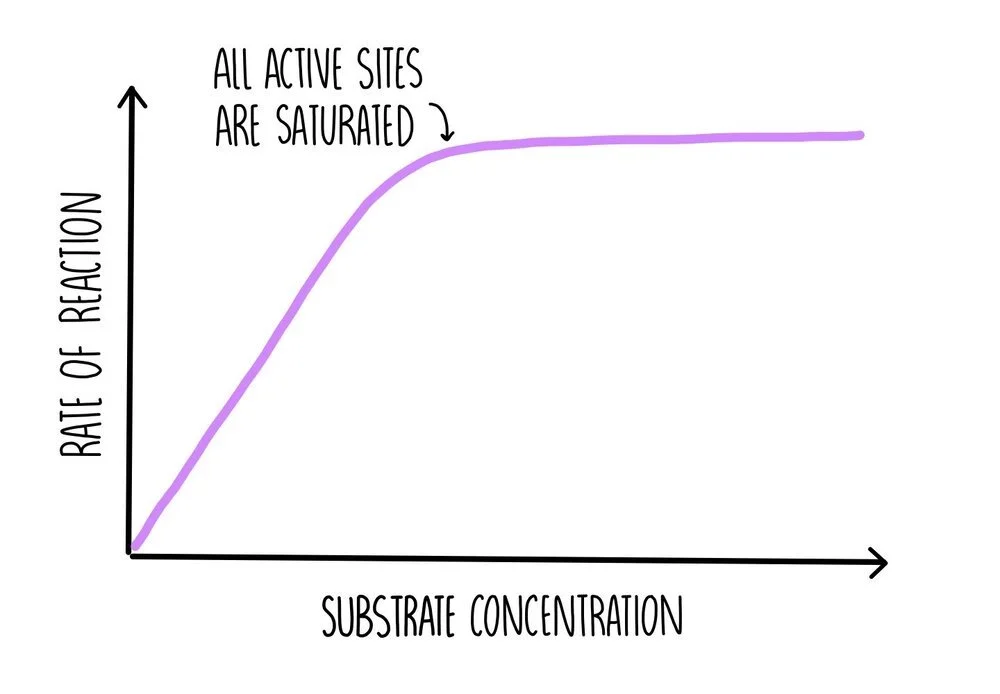

Substrate concentration

As substrate concentration increases, the rate of reaction increases since there are more substrate molecules to fill the enzyme’s active sites. There will be more frequent collisions so more formation of ES complexes. At some point a ‘saturation’ point is reached where all of the enzyme’s active sites are occupied with substrate molecules, so the addition of more substrate molecules will have no effect on the rate of reaction. At this point, the reaction is proceeding as fast as possible, which is referred to as Vmax. The only way the reaction can go any faster is by increasing enzyme concentration.

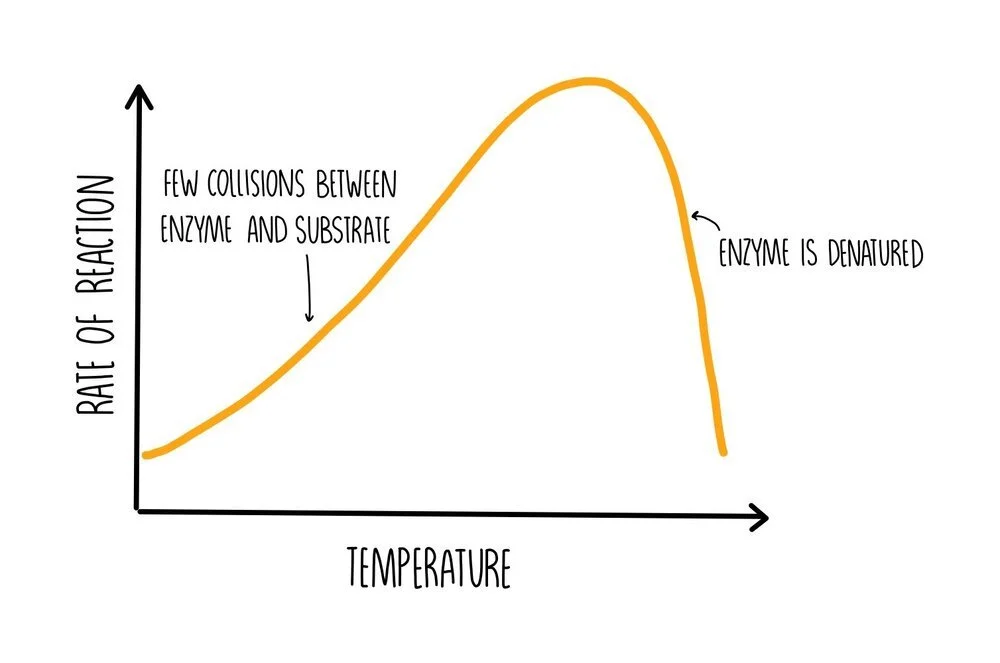

Temperature

At low temperatures, the rate of reaction will be slow because the enzyme and substrate have low amounts of kinetic energy. This means that there won’t be many collisions so there will be reduced formation of ES complexes. As the temperature is increased, the number of collisions increases, increasing the formation of ES complexes and increasing the rate of reaction. If the temperature becomes really high, hydrogen bonds will begin to break within the protein, causing it to unravel and become denatured. If enzymes are denatured, they lose the shape of their active sites which means they cannot bind to their substrate, decreasing the rate of reaction.

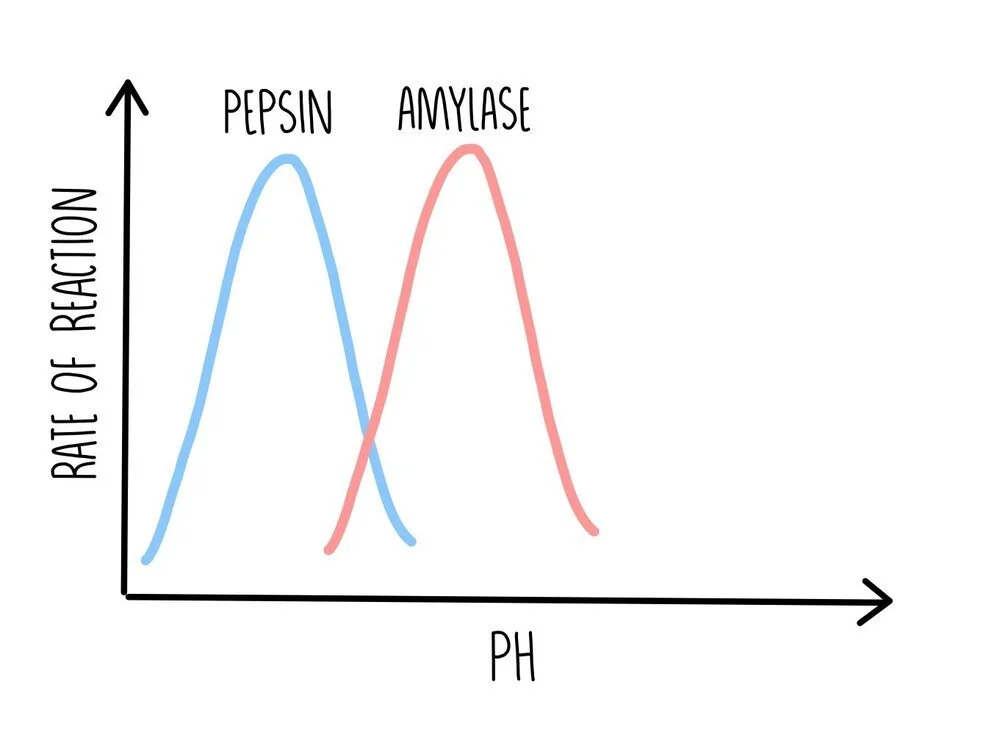

pH

Each enzyme has its own optimum pH at which it works best. Pepsin, the enzyme which digests protein in the stomach, works best in acidic environments whereas the enzymes responsible for the digestion of carbohydrates work better at a more neutral pH. Deviations from the optimum pH change the charge on the enzyme, which affects ionic bonding within its structure. Deviations in pH also break hydrogen bonds. This causes it to change shape and become denatured, decreasing the rate of reaction as pH deviates from the enzyme’s optimum conditions.

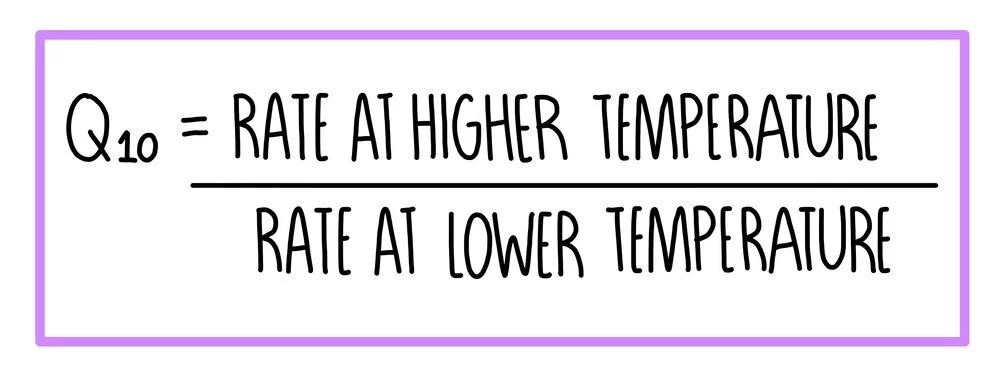

The temperature coefficient

The temperature coefficient, Q10, tells you how much reaction rate changes when the temperature is raised by 10 degrees. It is calculated using the equation:

When Q10 = 2, the rate is doubling for every 10oC increase in temperature. When Q10 = 3, the rate trebles for every ten degree increase. Most enzyme-catalysed reactions have a Q10 of around 2.

Investigating the rate of an enzyme-controlled reaction

There are two ways of measuring the rate of an enzyme controlled reaction: By measuring the speed at which product is formed or reactant is removed.

Measuring product formation using catalase

A good example of a reaction in which product formation is measured is the reaction catalysed by catalase, which breaks down hydrogen peroxide into oxygen and water.

Method:

Add a set volume/concentration of hydrogen peroxide to a test tube along with a set volume of buffer solution to control pH.

Place a bung on top of the test tube and connect to an inverted measuring cylinder using delivery tubing.

Using a pipette, add catalase the test tube. Quickly re-insert the bung and delivery tube.

Measure the volume of oxygen produced in the measuring cylinder every ten seconds for the first minute of the reaction (using a stopwatch to record the time).

Repeat two more times. Calculate the mean volume of oxygen produced at each ten second time interval.

Control variables: volume of catalase, volume and concentration of hydrogen peroxide solution, pH, temperature.

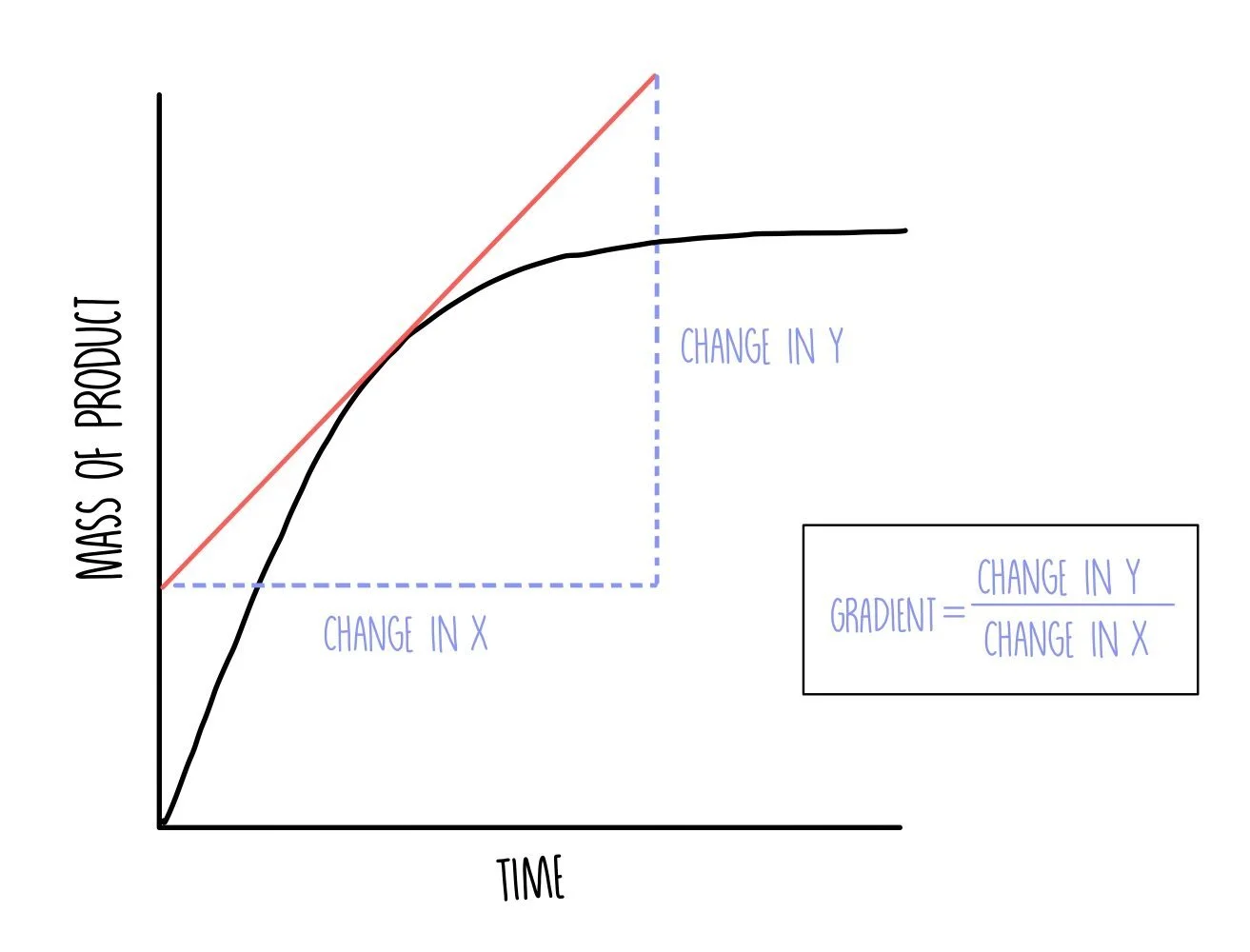

Plot a graph with time on the x-axis and volume of oxygen on the y-axis. You can determine the initial reaction rate by drawing a tangent to the curve at t = 0. Draw a straight line against the curve right at the beginning of the reaction and calculate the gradient by dividing the change in y by the change in x.

You can repeat the experiment with different concentrations of catalase to determine the effect of changing enzyme concentration on the initial rate of reaction.

Measuring reactant removal using amylase

Amylase is the enzyme which hydrolyses starch into maltose. You can measure decreasing starch concentration as the reaction progresses by adding iodine, which turns blue/black in the presence of starch.

Method:

Place a cuvette containing iodine solution in a colorimeter with a red filter. Zero the machine.

In a separate cuvette, pipette a given volume (e.g. 0.5 ml) of starch solution and a set volume of iodine solution. Mix together – the solution should turn blue/black. Place in the colorimeter and record the absorbance.

Add amylase solution of a set concentration/volume into the same cuvette and starch the stopwatch.

Record the absorbance of the solution every ten seconds.

Repeat the whole process two more times and calculate a mean absorbance for each ten second interval.

Control variables: concentration of iodine solution, volume of starch, pH, temperature.

Plot a graph with time on the x-axis and absorbance on the y-axis. You can repeat the experiment with difference concentrations of starch to determine the effect of changing substrate concentration on initial reaction rate.

Cofactors and coenzymes

Cofactors are non-protein molecules that need to be bound to an enzyme in order for it to work. Some cofactors are inorganic and work by helping the enzyme bind to its substrate. They aren’t involved in the reaction so they are chemically unchanged. For example, magnesium ions are cofactors for the enzyme DNA polymerase.

Other cofactors are organic molecules and are called coenzymes. These work by directly participating in the reaction so are chemically altered by the end of the reaction. They often carry chemical groups between different enzymes. For example, NAD+ is a coenzyme which transfers hydrogen (and electrons) between the enzymes involved in respiration. Many coenzymes are derived from vitamins.

When a cofactor is tightly bound to its enzyme, it’s called a prosthetic group. For example, the iron-containing heme group is a prosthetic group found in haemoglobin, forming a permanent part of its structure.

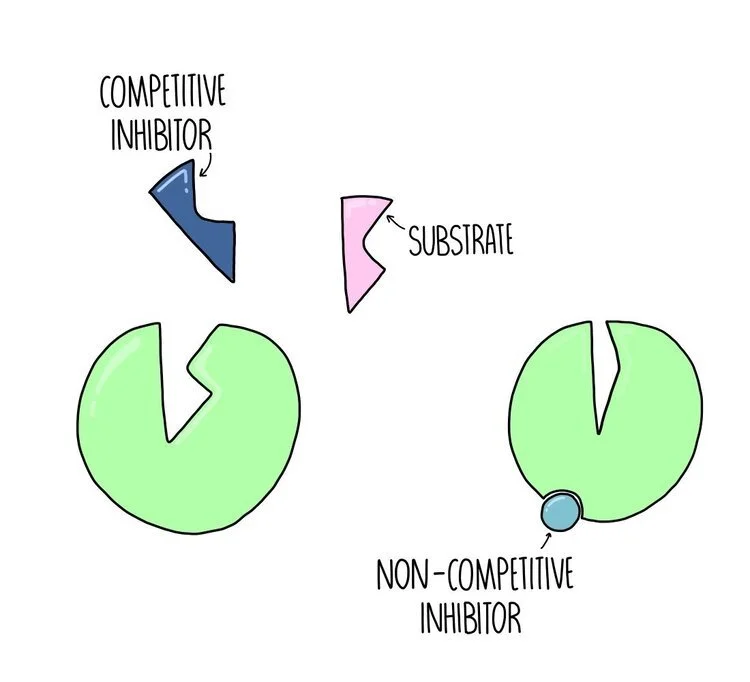

Competitive vs non-competitive inhibitors

Competitive inhibitors are ones which bind to the active site of the enzyme, blocking the substrate from binding - they compete with the substrate for access to the enzyme’s active site. The effect of a competitive inhibitor can be reduced by increasing substrate concentration. If there is way more substrate compared to inhibitor then the substrate is much more likely to collide with the enzyme’s active site.

Non-competitive inhibitors are ones which bind to a site on the enzyme away from its active site. This region is known as its allosteric site. The effect of a non-competitive inhibitor cannot be reduced by increasing substrate concentration.

Inhibitors can also be classed as reversible or irreversible. Reversible inhibitors form weak bonds (e.g. hydrogen, ionic bonds) with the enzyme and are easily removed. Irreversible inhibitors form strong covalent bonds with the enzyme and can’t be removed easily.

Some drugs and metabolic poisons act as enzyme inhibitors:

Antibiotics inhibit bacterial enzymes, such as transpeptidase, an enzyme involved in forming the cell wall. This weakens the cell wall, causing it to burst when water enters the bacterial cell by osmosis.

Cyanide is an irreversible inhibitor of cytochrome c oxidase, an enzyme involved in respiration. Organisms that have ingested cyanide will die due to a lack of cellular respiration.

Inhibiting enzymes is an important way of protecting cells. For example, digestive enzymes such as proteases are made in the rough ER and golgi before being secreted. To prevent proteases from degrading proteins inside the cell, they are first synthesised in an inactive precursor form. Part of the precursor molecule inhibits its activity. Once the proteases are secreted, a chemical reaction removes the precursor molecule and the enzyme becomes active.

End-product inhibition

End-product inhibition is when the final product in a metabolic pathway inhibits an enzyme that acts earlier on in the pathway. For example, glycolysis is the first stage of respiration and is made up of a series of reactions which converts glucose into energy (ATP). Phosphofructokinase is an enzyme which catalyses one of these reactions and is inhibited by ATP, preventing further glycolysis if plenty of energy is already available.

End-product inhibition is a good way of regulating metabolic pathways and controlling the amount of product produced. It is reversible, so when the product begins to drop, the enzymes will be able to function again to make more of the product.